Maximizing Profitability & Mitigating Complexities in Drug Manufacturing: AI-Powered Batch Yield Prediction

In the world of pharmaceutical manufacturing, batch processing stands as a cornerstone technique. It involves the production of large quantities of a drug, allowing for systematic and controlled processing. This method is indispensable for its ability to streamline production, enhance quality control, and facilitate regulatory compliance. However, achieving this goal has been made difficult by multiple challenges rooted in manual analysis, leading to suboptimal yield realization, and missed opportunities. These obstacles unfortunately contribute to staggering annual losses of nearly $50 billion. The solution lies in harnessing the power of artificial intelligence and data analytics to revolutionize the way we understand and optimize batch profitability in drug manufacturing.

Identifying roadblocks in batch processing

Recognizing key determinants of batch yield poses a crucial challenge in the drug manufacturing process. These determinants include factors like process control, equipment reliability, calibration, and batch size. Traditional manual processes are not only time intensive but also prone to errors which yield inaccuracies that obstruct in maximizing the output. With batch yield optimization, these issues can be resolved where adjustments in batch size and the various parameters mentioned earlier can enhance manufacturing analysis, and process control and improve outcomes.

Golden batch: The road to optimizing batch processes

The Golden batch manufacturing process is a system for identifying an ideal output and optimizing the manufacturing process to replicate the conditions that have produced it. The concept of a golden batch is invaluable providing dual advantages of reduced cost and increased revenue. The equation is straightforward: as yield improves, costs decrease. Achieving higher yield involves improving resource utilization, minimizing waste, and mitigating unplanned downtime, recalls, and out-of-tolerance process conditions. On the revenue front, the golden batch methodology prioritizes maintaining product quality and ensuring manufacturing consistency.

Key insights also play a pivotal role in shaping batch yield performance. Real-time analysis of batch performance provides instant access to critical information on raw materials and equipment performance. This streamlined approach aids in cutting down expenses related to rework and off-spec products. Extensive insights further emerge through benchmarking key performance indicators (KPIs) against the golden batch, pinpointing areas for potential process improvements. Integrating data from a process control system into a batch performance analytics solution effectively tracks the manufacturing process, offering clarity on when golden batch standards are met and identifying the reasons behind any specific batch issues.

In navigating the intricate landscape of multiple parameters, the golden batch methodology underscores the importance of optimizing key determinants to drive profitability. By homing in on these critical factors, businesses can strategically enhance yield and revenue while maintaining rigorous control over the manufacturing process.

Enhancing profitability with tcgmcube-enabled batch yield analysis

With the promise of improving yield and enhancing batch profitability, we at TCG Digital offer a transformative solution powered by tcgmcube, an end-to-end AI platform for efficient batch yield analysis.

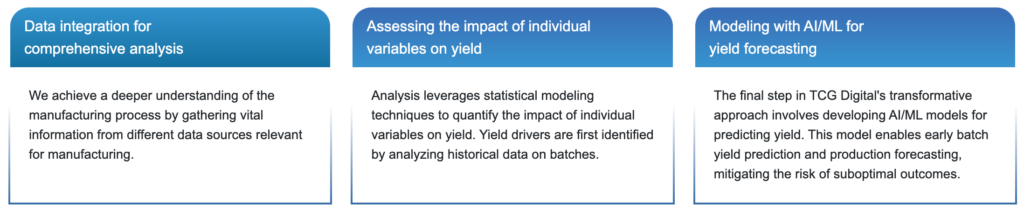

Our comprehensive solution comprises of

The greater the yield improvement, the greater the batch profitability

Harnessing the power of modern yield improvement solutions, tailored for process optimization and production forecasting, brings us closer to elevating batch profitability. These solutions provide a strategic advantage in navigating the complexities of today’s drug manufacturing industry by offering visibility into the key yield drivers. A comprehensive understanding of these drivers ensures effective yield management, culminating in heightened batch profitability.

Demystifying the critical determinants of the batch yield has never been easier. With our tcgmcube-powered batch yield solution, one can counter suboptimal yield realization and maximize output by understanding the key drivers.

To know more about how to better optimize the Batch Profitability, write to us at contact@tcgdigital.com