Introduction:

Reliability Beyond Conventional Predictive Maintenance

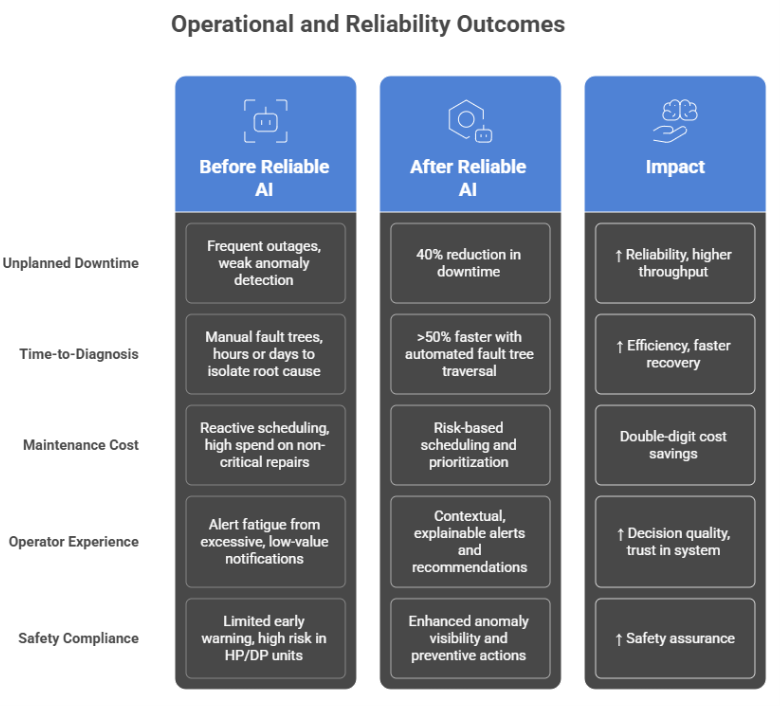

In asset-intensive industries such as refining, petrochemicals, and continuous processing, the financial, safety, and reputational implications of unplanned downtime are significant. Traditional predictive maintenance systems have improved reliability, yet they often fall short in critical areas:

- Weak signals of failure are missed until they escalate into major incidents.

- Operators face alert fatigue from excessive, non-prioritized notifications.

- Troubleshooting relies heavily on manual fault tree analysis, extending recovery times.

- Maintenance planning is decoupled from financial impact, limiting business alignment.

A leading petrochemical operator confronted precisely these issues within its high-pressure (HP) and depressurized (DP) operations. The organization required a framework that not only detected anomalies but also contextualized risks, accelerated resolution, and linked reliability directly to business outcomes.

The Challenge

The operator’s monitoring systems produced vast amounts of data but lacked the intelligence to distinguish critical events from background noise. Failures within HP instrumentation and DP process systems frequently progressed unnoticed until they triggered costly outages.

The core challenges were:

Unclear alert prioritization, leading to resource misallocation.

Manual, time-intensive root cause analysis that slowed recovery.

Limited financial visibility, making it difficult to align reliability initiatives with business priorities.

The Reliable AI Intervention

To address these challenges, the operator deployed Reliable AI, an agentic framework leveraging Generative AI and Large Language Models (LLMs). The solution integrated anomaly detection, predictive modeling, and intelligent retrieval to provide actionable, plant-specific insights.

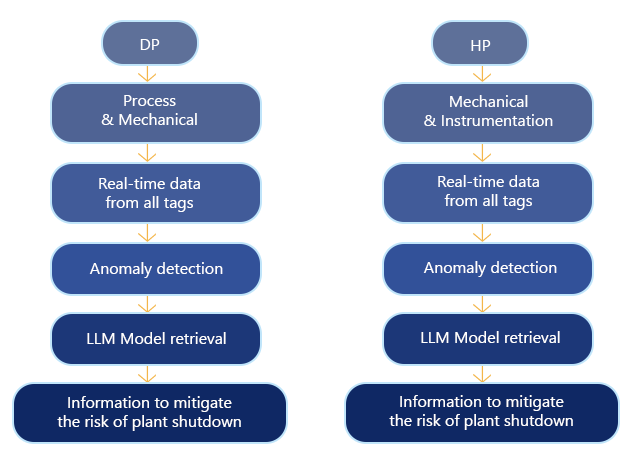

The following framework illustrates how Reliable AI was applied across HP and DP operations to detect anomalies and generate actionable insights.

How GenAI Strengthened Reliability

From unstructured data to insights

Contextual diagnostics

GenAI connected new anomalies with past incidents, highlighting likely causes and recommended fixes based on plant-specific history.

Adaptive learning loop

As engineers validated or rejected AI recommendations, the model continuously refined its accuracy, improving predictive reliability over time.

Natural-language interaction

Engineers could query the system in everyday language “Show me previous DP compressor failures with similar vibration patterns” and receive precise, context-aware answers.

Key components included

Anomaly Detection

RAG-Based Retrieval

Plant-specific historical incidents and resolutions were embedded into the model, allowing rapid recall of relevant precedents.

Financial Overlay

Reliability risks were evaluated not only technically but also in terms of cost, downtime impact, and production losses.

Predictive Modeling with Tagged Data

Systematic use of historical attributes (anomaly status, cause, temporary and permanent fixes) enabled forecasting of failures.

Automated Fault Tree Traversal

The AI streamlined diagnostic workflows, significantly reducing time-to-resolution.

The Results

Within six months of deployment, the operator achieved measurable and business-critical improvements across its HP and DP operations.

Strategic Implications

Building on the success of the initial deployment, the operator is extending Reliable AI across additional facilities, embedding reliability as a core driver of operational performance. The broader implications are both immediate and forward-looking:

Operational Relevance

Plant-specific insights reduced downtime and alert fatigue, proving that GenAI can be integrated into daily engineering workflows without overwhelming operators.

Business Alignment

By overlaying financial metrics on reliability risks, maintenance actions were directly tied to profitability, capital efficiency, and risk reduction.

Autonomous Reliability Agents

Future versions will be capable of executing routine maintenance decisions with minimal human intervention.

Deeper Financial Integration

Asset reliability metrics will be directly correlated with profitability, risk exposure, and shareholder value.

Cross-Sector Scalability

The framework shows strong applicability in power, utilities, and discrete manufacturing, extending benefits beyond petrochemicals.

Evolving Engineering Roles

As automation reduces routine analysis, engineers will shift from reactive troubleshooting to proactive optimization and reliability strategy.

Interested in what lies ahead? You can watch our webinar, “Case Discussion: Asset Reliability and Operational Excellence using Gen-AI and AI in Process Industries,” on demand. Register to access the full recording and explore these future developments in detail.

Conclusion

The case of this petrochemical operator underscores how Reliable AI redefines predictive maintenance. By bridging anomaly detection, contextual reasoning, and financial visibility, the framework reduced downtime, optimized maintenance, and strengthened safety.

This demonstrates that the future of plant reliability lies not in more data or dashboards, but in intelligent, adaptive systems that augment human expertise with real-time, context-rich, and business-aligned guidance.

Reliable AI moves beyond monitoring, providing a practical framework for achieving higher reliability and operational resilience.